When working with power tools, user comfort and safety are paramount. Excessive vibration from power tools can lead to user fatigue, reduced precision, and long-term health issues such as Hand-Arm Vibration Syndrome (HAVS). Recognizing these challenges, Makita has developed an innovative solution: Anti-Vibration Technology (AVT).

This guide explores Makita's AVT, detailing its features, benefits, and the tools that incorporate this groundbreaking technology.

UNDERSTANDING ANTI-VIBRATION TECHNOLOGY (AVT)

Makita's Anti-Vibration Technology (AVT) is a sophisticated system designed to significantly reduce the vibration levels generated by power tools. By integrating AVT, Makita aims to enhance user comfort, improve tool control, and minimize the adverse health effects associated with prolonged exposure to vibration.

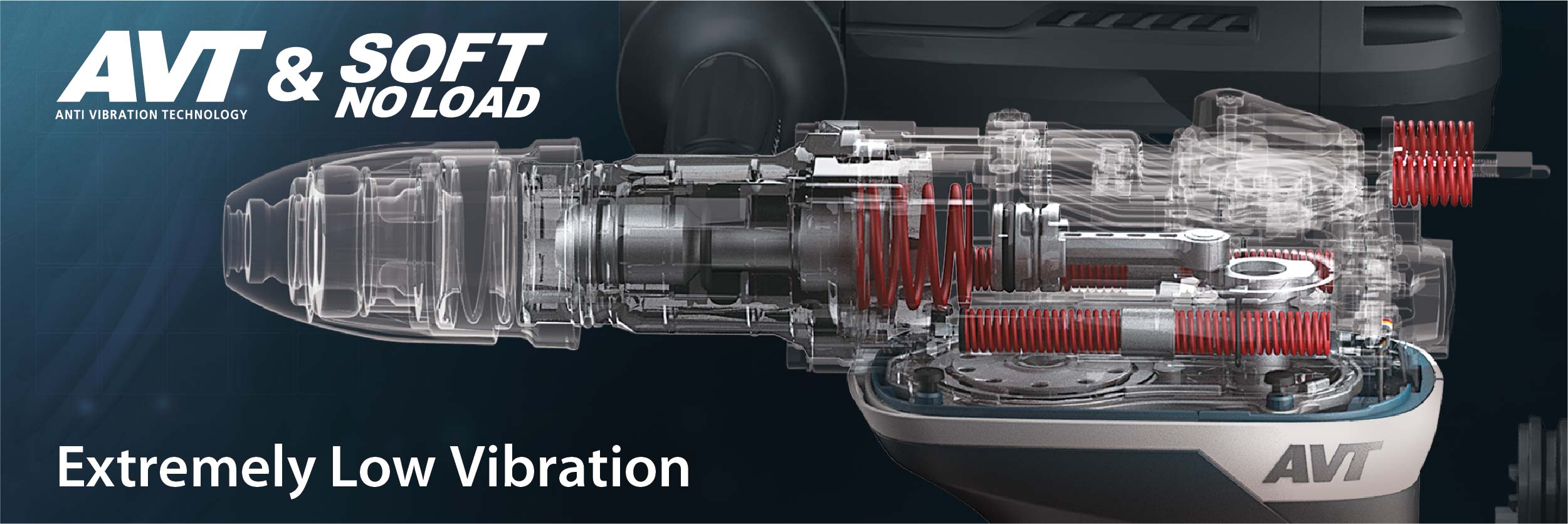

HOW AVT WORKS

AVT operates through a combination of advanced engineering techniques and components that work together to dampen vibrations. The core elements of AVT include: One of the key elements in AVT is the use of specialized materials that effectively absorb vibrations.

Dynamic Vibration Absorber

This component acts as a counterbalance, moving in the opposite direction to the tool's main vibration source. By doing so, it helps neutralize the vibrations, resulting in a smoother operation. This innovative feature distinguishes our tool from the competition, enhancing its performance and durability.

Integrated Damper Spring

The damper spring absorbs and dissipates the vibrations produced during tool operation. This spring is strategically placed to maximize its vibration-reducing effect. By minimizing vibrations, the damper spring enhances user comfort and reduces fatigue during extended use.

Isolated Motor Housing

By isolating the motor housing from the handle, AVT prevents the transmission of vibrations to the user's hand. This design minimizes the direct impact of the tool's vibrations on the operator.

Counterweight Mechanism

Some AVT-equipped tools feature an internal counterweight system that moves in the opposite direction to the main moving part of the tool. This mechanism helps balance the tool and further reduce vibration.

BENEFITS OF AVT

Enhanced User Comfort

By reducing vibration, AVT makes using power tools more comfortable, even during prolonged tasks. Users experience less fatigue and can maintain higher levels of productivity throughout the workday.

Improved Precision

Lower vibration levels allow for better control and accuracy. This is particularly beneficial for tasks requiring fine detail and precision, such as chiseling or drilling.

Health and Safety

AVT helps mitigate the risk of Hand-Arm Vibration Syndrome (HAVS) and other health issues associated with long-term exposure to vibration. This is crucial for professionals who use power tools regularly.

Extended Tool Life

By reducing the internal stresses caused by vibration, AVT can contribute to the longevity of the tool itself. This results in lower maintenance costs and fewer replacements over time.

Makita Tools with AVT

Makita has incorporated AVT into a wide range of its power tools, ensuring that users across various trades can benefit from this technology. Some notable examples include:

Rotary Hammers

Makita's rotary hammers with AVT are designed for heavy-duty tasks like concrete drilling and chiseling. Models such as the HR4013C and HR5212C feature AVT for enhanced comfort and performance.

Demolition Hammers

The HM1214C and HM1812 are demolition hammers equipped with AVT, making them ideal for breaking up concrete and other tough materials while minimizing user fatigue.

Reciprocating Saws

The JR3070CT reciprocating saw incorporates AVT to provide smoother cutting experiences, reducing vibration and improving control during demolition and renovation tasks.

Concrete Planers

Concrete planers like the PC5010C with AVT offer superior control and reduced vibration, making them perfect for surface preparation and finishing.

USING AVT-EQUIPPED TOOLS EFFECTIVELY

To maximize the benefits of Makita's AVT, users should follow these best practices:

Proper Grip

Maintain a firm yet comfortable grip on the tool, allowing the AVT components to function effectively. Ensure your grip on the tool is both secure and comfortable to optimize the performance of the AVT components.

Appropriate Pressure

Apply consistent, moderate pressure during operation. Excessive force can counteract the vibration-reducing mechanisms.

Regular Maintenance

Keep the tools clean and well-maintained to ensure that AVT components remain in optimal working condition.

THE FINAL SAY

Makita's Anti-Vibration Technology (AVT) represents a significant advancement in power tool design, offering numerous benefits that enhance user comfort, precision, and safety.

By integrating AVT into a wide range of tools, Makita has set a new standard for vibration control, making it easier for professionals to perform demanding tasks with less fatigue and greater accuracy. Whether you’re drilling, chiseling, sawing, or planing, Makita's AVT-equipped tools provide a smoother, safer, and more efficient working experience.